Features

01/Feeder

No extra adjustment for different sheet sizes, paper weight ranges from 120 gsm to 600 gsm., easy to operate. Sufficient operation space due to no suction feeder above paper piles; Ideal low E-type piling plate and high speed lifting device ensures quick paper piling to save time and increase efficiency. Pre-loading device by rail equipped as standard. |

02/Bottom sheet feeding section

A large fan is used at the bottom paper conveying to control the suction air volume, making the bottom paper feeding smoother; A large fan is used at the bottom paper conveying to control the suction air volume, making the bottom paper feeding smoother;The suction belt is wider, longer and thicker, and controlled by the servo drive for more stable paper feeding; Thoroughly solve the problem of paper bending and warping on four or more layers; When the flute paper bends, the pneumatic pressure strip can press the front end of the flute paper to ensure smooth paper feeding. |

03/Gluing section

High precise coating stainless steel roller mechanism assures even adhesive applied. High precise coating stainless steel roller mechanism assures even adhesive applied.Special mechanism ensures paper stripping off the gluing roller, easy to clean, dismantle and adjust Three sensors to control the glue volume level automatically. Side Glue stopper ensures no overflow at high speed and glue re-circulation at high speed. |

04/Register section

Multi sensors to monitor feeding position of the bottom sheets, the upper two servo motors (Japanese Yaskawa brand) adjust the top sheets synchronously to make accurate register during lamination.

|

05/Compress conveyor

The laminated sheets collected by press conveyor as standard for perfect bonding. The conveyor speed is adjustable as per the machine speed.

|

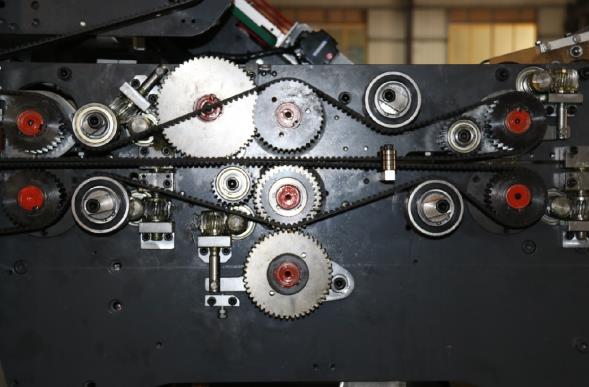

06/Compress conveyor

Power transmission evenly distributed by gears and belts combination, maintenance free, low noise, high efficiency. |

07/Compress conveyor

Man-machine interface with PLC touch-screen control, warning light indicator, automatic monitoring of production condition, irregularities and job record. CE certified. |

Specification |

Model | FL 145 | |

Max. Sheet Size (W*L) | 1450*1450mm | |

Min. Sheet Size (W*L)

| 400*350mm | |

Thickness | Top sheet | 120~600gsm |

Bottom sheet | 0.5-10mm(B,A,AB,E flute, etc.) | |

Laminating Accuracy | ±1.5mm | |

Max. Speed | 150 m/min (Subject to board quality and specification) e.g. around 10,000 sheets/hour at length 600mm | |

Power | 26kw | |

Dimension L*W*H | 12870x2496x2619mm | |

stment for different sheet sizes, paper weight ranges from 120 gsm to 600 gsm