Benefits and Features

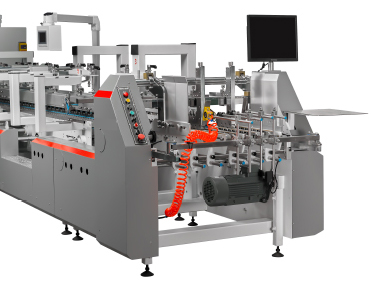

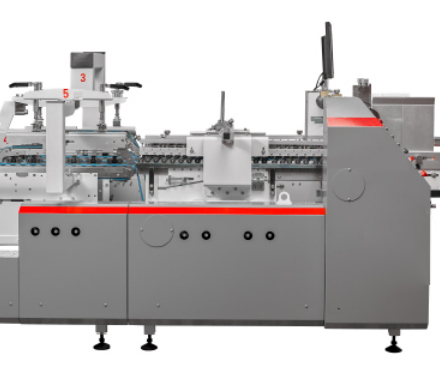

01/Feding Unit

● Independent motor frequency conversion drive; ● A number of high-quality thickened belts and electric paper stacking vibration device ensure accurate and smooth feeding; ● The adjustment of each mechanism in the feeding unit is convenient and easy, which shortens the setting and job changing time; ● There are 2 sets of main knife / auxiliary knife for feeding; |

02/Side Register Unit

● Make sure that the paperboard is accurate and straight before entering the folding process |

03/Pre-Folding Unit

● It is suitable for the products that need to enter the automatic packaging line, fold No.1 creasing line 180 degrees and No.3 cr easing line 135 degrees, so as to facilitate the opening of the product when filling the material. ● It can also provide auxiliary folding function for boxes that need to be folded many times. |

04/Crash Lock Bottom Unit

● Large / medium / small complete set of lock bottom parts to ensure the accurate and smooth production of different sizes of lock bottom box; ● The upper pressure transmitter is of retractable design, which can be flexibly adjusted according to different lock bottom boxes; ● Open mechanism design, easy to operate, convenient to disassemble and install |

05/Gluing Unit

● Both the left and right bottom gluing units can be used to micro-adjust the glue volume individually; ● The upper gluing device is the high-speed electronic glue gun spraying system; ● Disassembly and installation is convenient, easy to clean and maintain; |

06/Final Folding Unit

● Extended long journey design, so that the paperboard can fully stretch here, and the second line & the fourth line can be naturally shape into form; ● Left and right folding belt 180 degrees independent speed adjustable; |

07/Trombone Unit

● The upper and lower transporters are driven separately, which are suitable for all kinds of long and short boxes; ● Continuous and automatic carton accumulation ensures the natural and smooth accumulation of cartons of different sizes in this part; ● Alignment device. ● Equipped with automatic kicking & counting device; |

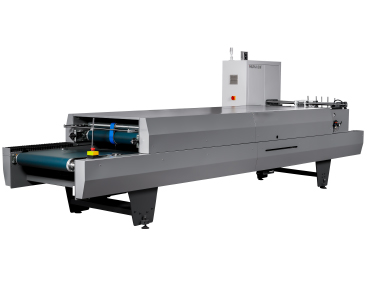

08/Conveying Unit

● The pneumatic pressure adjustment design can adjust the applied pressure accurately; ● Using two independent imported belts, soft and moderate, with sponge belt, to ensure that the product will not damage the surface in the process of glue curing. ● The speed of the conveyor is adjusted automatically according to the rotation speed of the main engine, and the manual operation mode and speed can also be selected; |

09/Back Folding Device

● The independent main control panel is easy to operate and master; ● Two groups of high-precision servo motors drive the electronic back-folding system and cooperate with the motion controller to ensure the accurate movement of the two servo shafts in high-speed operation; |

Optional Configuration

4/6 corner devices | Memory storage | Automatic box collecting device |

Wave Lock Bottom Device | Braille | Quality Inspection |

Hot glue system | Stereo Box | Glue detection system |

Plasma treatment system | Scratch-resistant Feeder | Coding Online/Bar Code Detection |

90/180 Turning | Thin Paper Feeder | Automatic rejection device |

Technical Parameters

Model | 70 | 90 | 120 | |

Processing material | Cardboard | 180-800 g/m² | ||

Corrugated flute type | N,F,E | |||

Performance | Max.speed | 400m/min | ||

Inching Speed | 20m/min | |||

Max. feeding width | 690mm | 850mm | 1200mm | |

Max. feeding width | 130mm | 140mm | 190mm | |

Way of Pre-fold | First folding line 180 degree, and the third folding line 135 degree | |||

Type of glue | Cold glue/Hot melt glue/PUR glue | |||

Electrical installation (C/AC/FC/FCW) | Required power | 21KW | 25KW | 30KW |

Compressed air | 6bar | |||

Air compressor capacity | 10m³ /h | |||

Air tank capacity | 60L | |||

Machine dimension | L | 14.5m | 15.2m | 16.3m |

W | 1.40m | 2m | ||

H | 1.5m | 1.7m | ||

Weight | 8Ton | 8.5Ton | 11.6Ton | |

Equipment characteristics

400m/min speed

Modular organization that can be expanded at any time and flexibly control various types of carton orders

Variable frequency motor independent segmented transmission

Wireless remote control adjustment makes operation simple and fast

Applicable Material

Carton board、Corrugated board、Plastic sheet

Production Box Type

|

|

|

|

|

|

One-side gluing | 4- Corner | Bottom gluing | 4- Corner with Lid | Double-wall gluing | 6- Corner |

Carton Specifications |

Model | One-side gluing | Double-wall gluing | Bottom gluing | 4-Corner | 4- Corner with Lid | 6-Corner |

|

|

|

|

|

| |

1450 | W 450(290)-1450mm H 250-1200mm E 140-720mm | W 290-1450mm H 200-1200mm D 50-200mm E 140-1250 | W 290-1370mm H 250-1000mm E 140-680m | W 230-1450mm H 220-1200mm E 30-150m | W 350-1300mm H 220-1200mm E 30-150m | W 50-1300mm H 220-1200mm E 30-150mm |

1650 | W 450(290)-1650mm H 250-1200mm E 140-820mm | W 290-1650mm H 200-1200mm D 50-200mm E 140-1450 | W 290-1570mm H 250-1000mm E 140-780mm | W 230-1650mm H 220-1200mm E 35-150m | W 350-1500mm H 220-1200mm E 30-150m | W 350-1500mm H 220-1200mm E 30-150mm |

1850 | W 450(290)-1850mm H 250-1200mm E 140-920mm | W 290-1850mm H 200-1200mm D 50-200mm E 140-1650 | W 290-1770mm H 250-1000mm E 140-880mm | W 280-1850mm H 220-1200mm E 30-150mm | W 350-1500mm H 220-1200mm E 30-150mm | W 350-1700mm H 220-1200mm E 30-150mm |

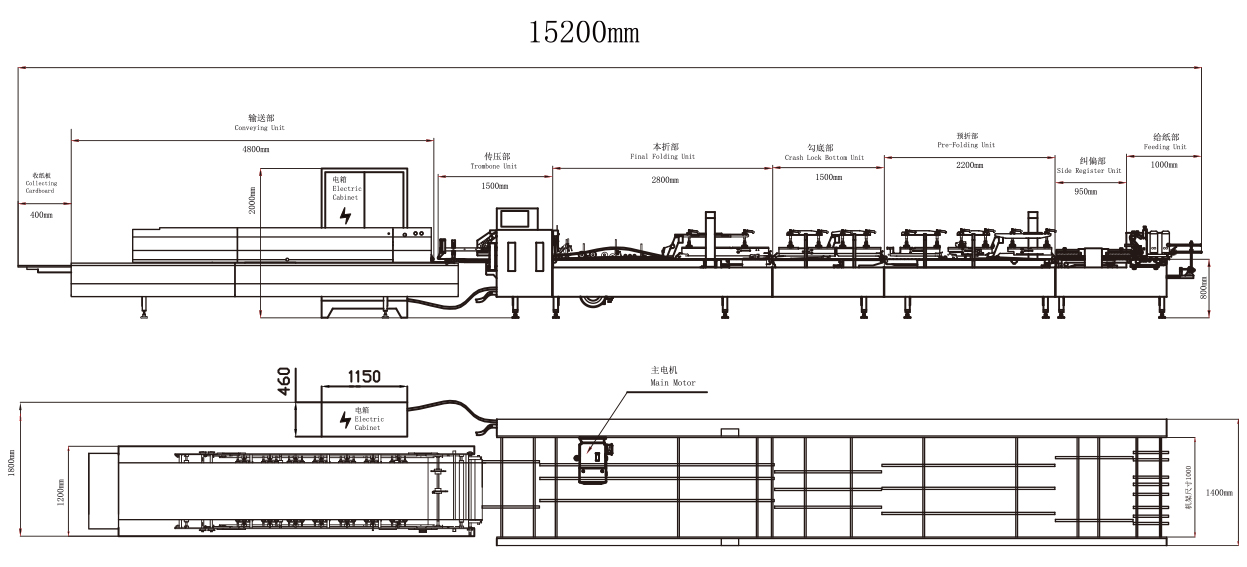

Basic floor plan

Model | Length (mm) | width (mm) | width (mm) |

70 | 14500 | 1300 | 1500 |

90 | 15200 | 1400 | 1500 |

120 | 16300 | 1580 | 1700 |