Features

01/FEEDING UNIT

High precision feeding head which can smoothly running with thin paper and all kinds of cardboard in high speed.Equipped with gantry type preloading mechanism.Main and vice feeding platform working by turns to achieve non-stop running. |

02/CONVEYING UNIT

Vacuum conveying system which can ensure thin paper stable and precise conveying.Equipped with Taiwan push-and-pull dual purpose guide lay to make stable positioning in high speed running;conveying wheel quick adjusting mechanism which can ensure high working efficiency. |

03/FOIL STAMPING/DIE CUTTING UNIT

Anti-deformation heat-resisting cast iron honey comb plate;Pressure regulating device adopt gapless ballscrew to make sure precise and stable pressure adjusting;Independent 20 heating zones control temperature,precisely controlled heating system,which can ensure stable temperature of the foil stamping die and balanced temperature control of the whole heating system. |

04/DIE CUTTING STEEL PLATE FINE-ADJUSTING DEVICE

Steel plate fine adjusting device which can revise the bottom die quickly,improving working efficiency greatly. |

05/LONGITUDINAL HIGH POINT FOIL FEEDING UNIT

Longitudinal three shafts high point foil feeding system and extension type foil release frame can make quick and convenient foil changing,transverse two shafts servo control foil feeding system,disrupted foil checking system. |

06/LONGITUDINAL FOIL DELIVERY UNIT

External longitudinal hair roller foil delivery system is convenient for waste recovery and recycle. |

07/DELIVERY UNIT

Delivery unit adopts hair brush and back sucking system to make tidy paper stack; Electric vice delivery device can achieve non-stop running;pneumatic sampling function. Label mark counting function is optional. |

08/FOIL STAMPING CONTROL SYSTEM

Intelligent arithmetic system can make automatic calculation of leapfrog project for different products,which can save foil greatly. |

Specification |

Model | TFoil 106 |

Max. Sheet Size | 1060x760mm |

Min. Sheet Size | 390x280mm |

Min. Front Margin | 8~17 |

Max. Foiling Size | 1050x745mm |

Max. Foiling Pressure | 600Tons |

Sheet Grammage | 80 ~ 2000g/m2 |

Max. Machine Speed | 8000 sheet/h |

Max. Height of Feeding Pile | 1600mm |

Max. Height of Delivery Pile | 1350mm |

Foiling Precision | ±0.075mm |

Total Power | 53 Kw |

Heating System | 20 independent heating zones, 0℃-200 ℃ adjustable temperature |

Foil Shaft | V3+H2 |

Machine Weight | 25Tons |

Dimension (L*W*H) mm | 8028*4966*2559 |

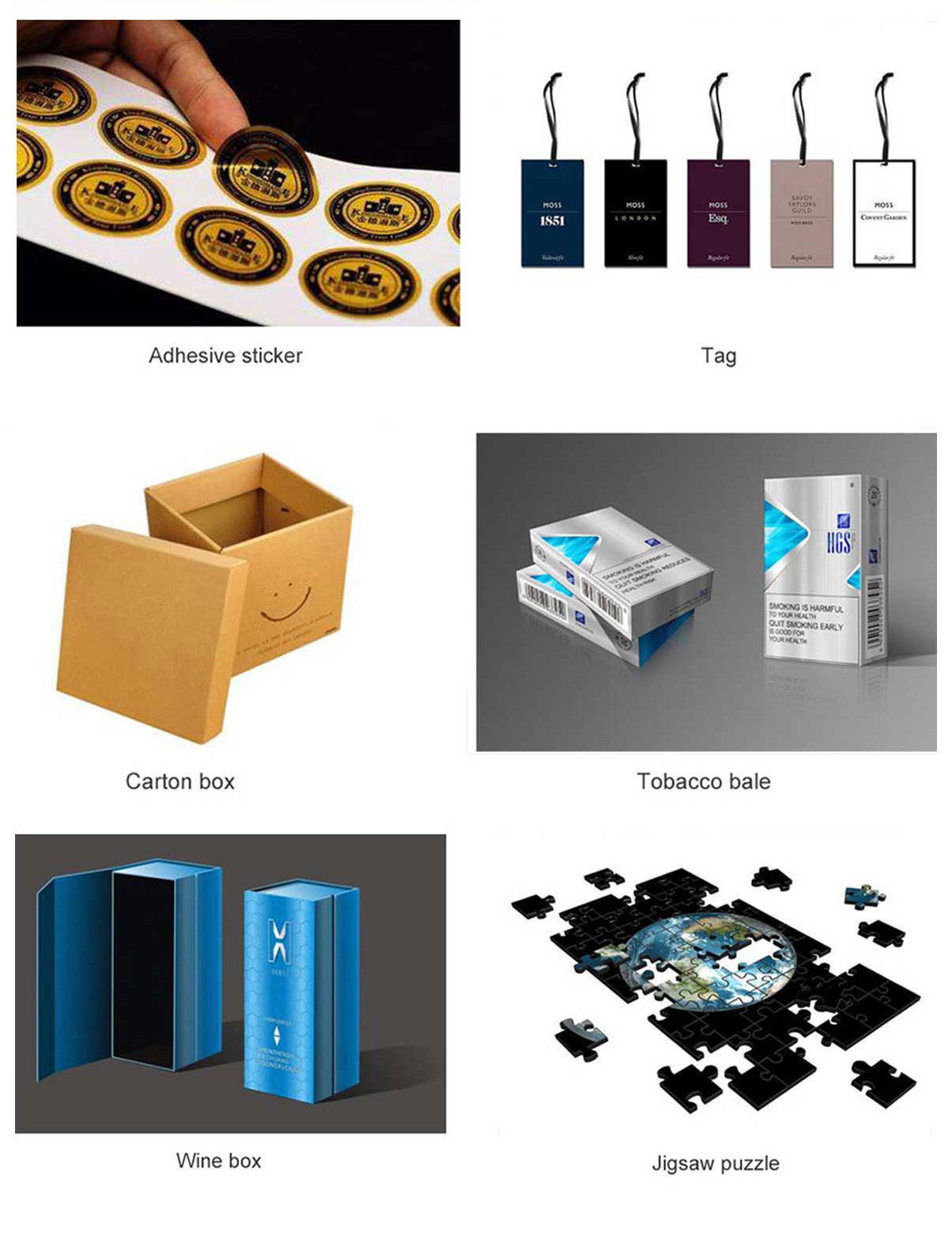

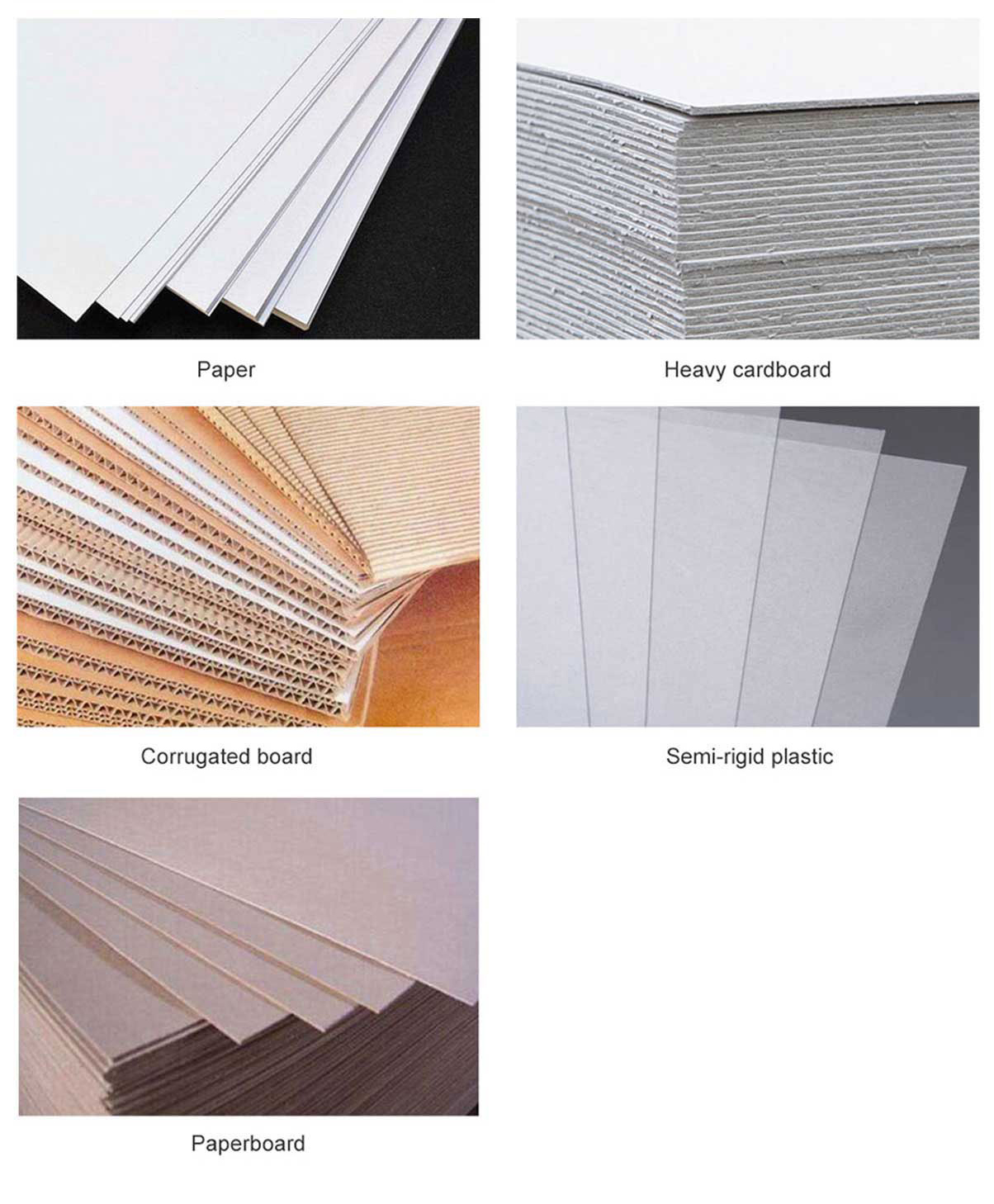

Application materials |

Application |