Features

TFoil 105, adds holographic positioning function on the basis of automatic embossing foil stamping die cutting machine. It is the prefect combination of embossing and foil stamping. Under 580 tons high pressure, the foil stamping process has achieved a qualitative leap, no matter in the scope, flatness and delicacy. With the effect of embossing, it makes the packaging more magnificent.

A.Feeder

High speed feeder, made of special alloy material, adopts 4 suction 4 feed strong suction nuzzles. And it can be adjusted the front, back, high and low, according to the paper, ensures the stable paper feed from 60 g/m2 thin cardboard to 2000 g/m2 carton. The eliminating static electricity device, makes paper feeding more stable and ensures a high precision of subsequent work. |

B.Paper feeding section

Tilting paper feed table, more suitable for the transport and positioning of thin paper under high speed. The pull and push gauges can be adjusted according to the paper situation, easy to operate. In place deceleration mechanism to make the conveying process more stable. Double paper check device, ensures the safety of the paper feeding and avoid paper waste. |

C.Die cutting section

German imports of die cutting bottom, hardness up to 53HRC. Pneumatic locking plate, pneumatic clutch, coupled with novel drive system, to achieve high speed stable die cutting. Unique die cutting board and frame effectively prevent die cutting plate sagging or falling off. |

D.Main motor section

The main part of the main engine , crankshaft, worm&gear, worm wheel, elbow, are all made of imported high end alloy material, coupled with our unique hand-work scraping craft, improve the operation life and stability of the main motor greatly. The turbo crank drives the high precision plane die cutting table, which ensures the level and accuracy of die cutting work. |

E.Pneumatic clutch

Pneumatic clutch imported from OPMI Italian, which effectively reduce the noise during machine operation and the aerodynamic impact. Combined with electric digital display, it controls the rise and fall pressure of die cutting platform simply and accurately. |

F.Index driver and torque limiter

Index driver and torque limiter imported from Taiwan , which uses the latest technology multi-chip parallel CAM index chain-row transmission device with long service life. The high sensitivity not only ensures the safety of the machine runing ,and also the operator。 |

G.Tooth row chain

The tooth row and the chain are made of special super rigid aluminum alloy from Taiwan, the surface of them is anodized, which achieve a high precision die cutting and embossing work on the high speed, also controls perfectly. The main transmission chain of the tooth row adopts the special chain of Reinaud Germany, the strength of the which is enhanced by 45%, extends the service life and improves the stability of the machine operation. |

H.Delivery section

The non- stop delivery device makes automatic paper collection orderly, improves work efficiency greatly. Non-stop sampling device views the die cutting paper situation at any time. Stepped-adjustable brush and paper blowing device collect finishes products orderly. |

Specification |

Model | TFoil 105 |

Max. Sheet Size | 1050x750mm |

Min. Sheet Size | 400x310mm |

Min. Front Margin | 8~17 |

Max. Foiling Size | 1040x720mm |

Max. Foiling Pressure | 580Tons |

Sheet Grammage | 80 ~ 2000g/m2 |

Max. Machine Speed | 7500 sheet/h |

Max. Height of Feeding Pile | 1600mm |

Max. Height of Delivery Pile | 1350mm |

Foiling Precision | ±0.075mm |

Main Motor | 24 Kw |

Heating System | 12 independent heating zones, 0℃-200 ℃ adjustable temperature |

Foil Shaft | V3+H2 |

Machine Weight | 16.8Tons |

Dimension (L*W*H) mm | 7400*4200*2100 |

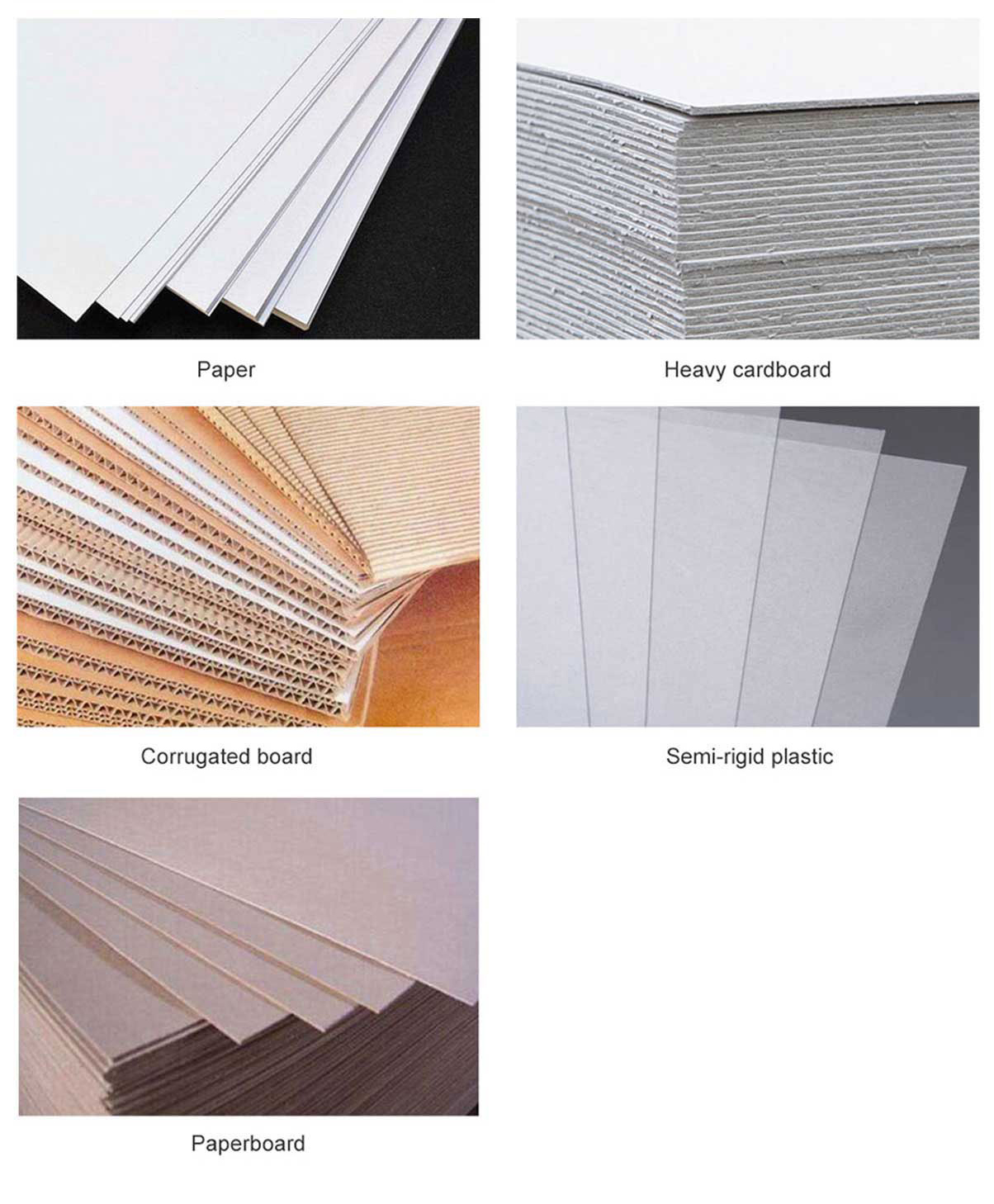

Application materials |

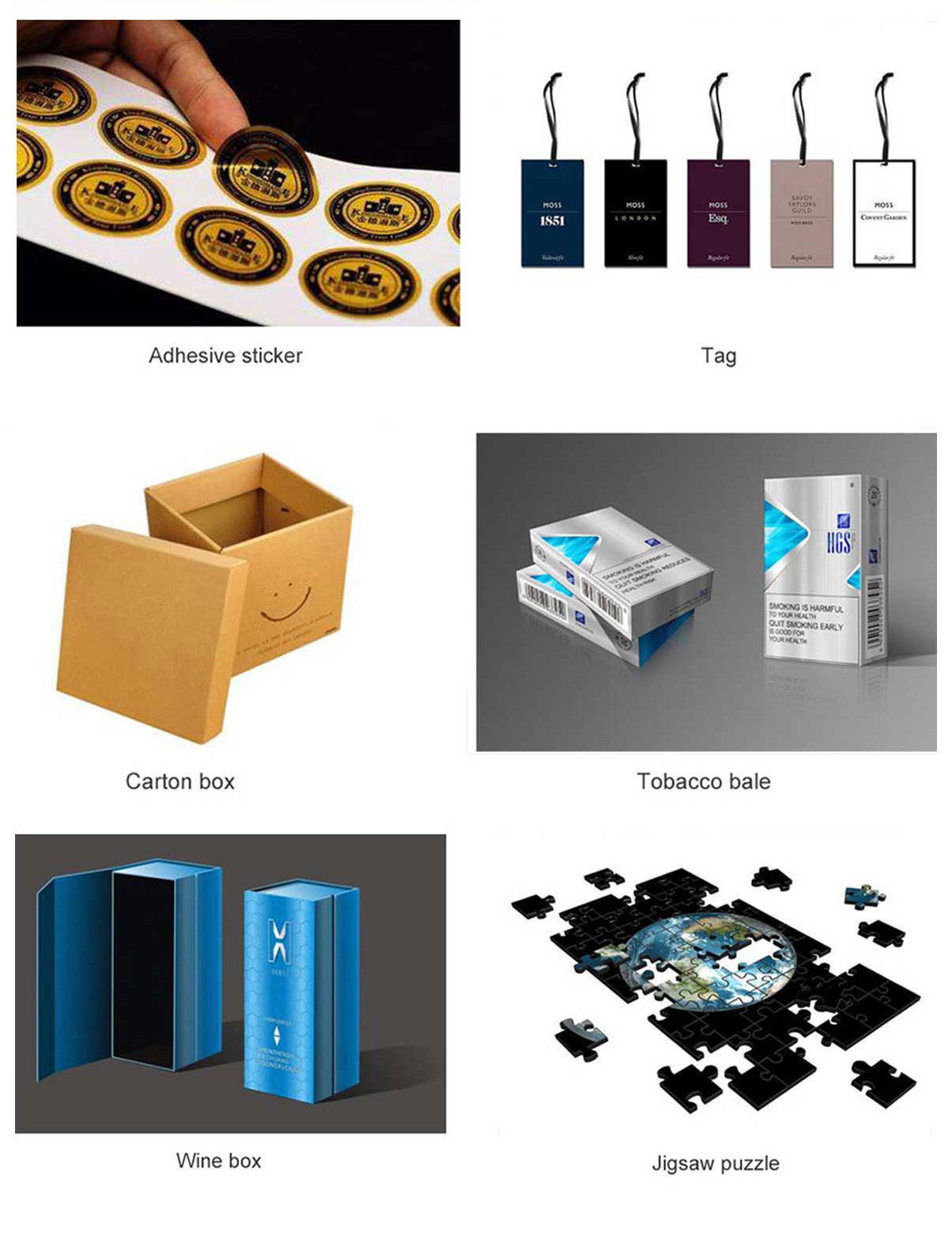

Application |