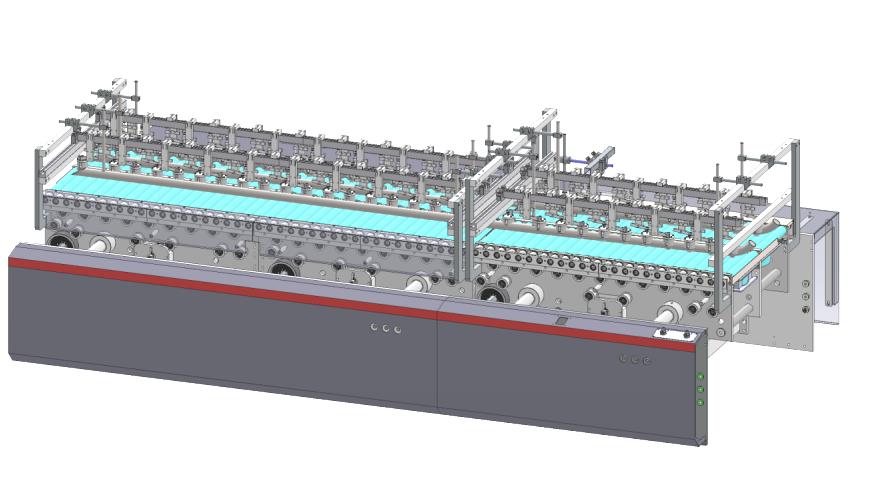

Specification |

Paper thickness | 200-1200 g/m², F, E flute corrugated board |

Binding Solvent | Water-soluble adhesive |

Machine Dimensions | 34910x1886x2100mm |

Power Consumption | 82kw |

Machine Speed | 300m/min |

Weight | 22500kg |

Blank Size |

| C:300 --1150 mm E:200--570 mm |

Features

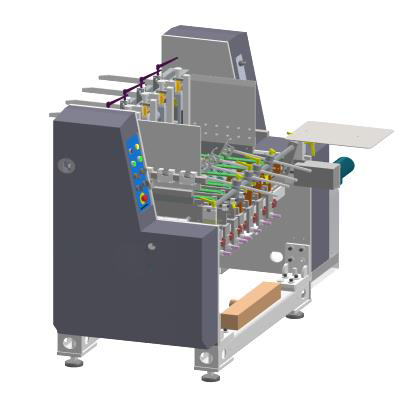

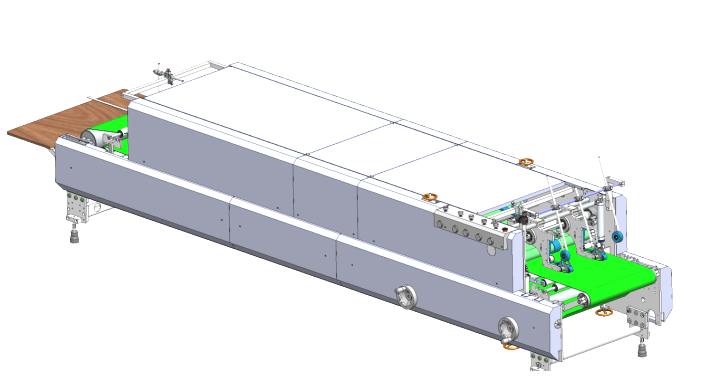

01/Feeding Unit

Independent servo motor drive ensures flexible adjustment, wider product adaptability, and constant torque output; Imported feed belts; |

02/Alignment Unit

Calibration ruler enables rapid positioning adjustments Configurable left/right orientation guidance |

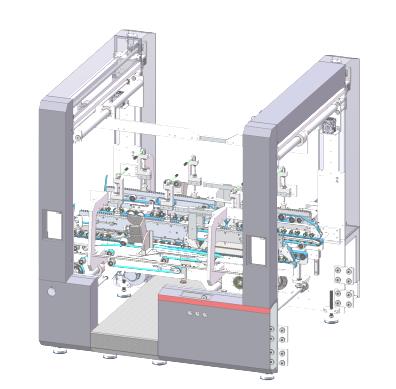

03/Intermittent Dotting Unit

Independent servo-driven upper/lower dies ensure high-precision, high-speed dotting Pneumatic lift system enables quick die replacement Extended base frame with three-position sliding plate system ensures stable product transfer and expanded workspace |

04/Glue Spraying Unit

Modular spray guns with one-touch lift mechanism simplify nozzle cleaning and reduce setup time Three-position plate system guarantees high-speed box transfer stability |

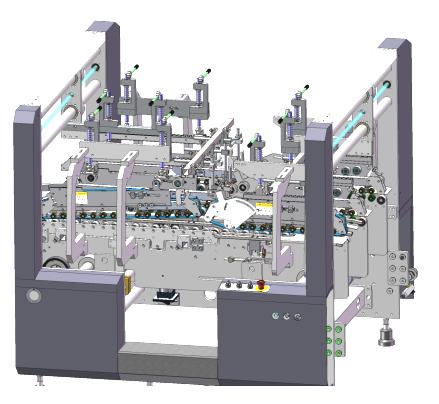

05/Folding Unit

One-touch pneumatic lift for pressure belt plates Three-position sliding plate structure with modular design enables rapid setup |

06/Folding Unit (Supplementary)

Rear pressure rollers on folding belts ensure rational and reliable product bonding User-friendly ergonomic operation |

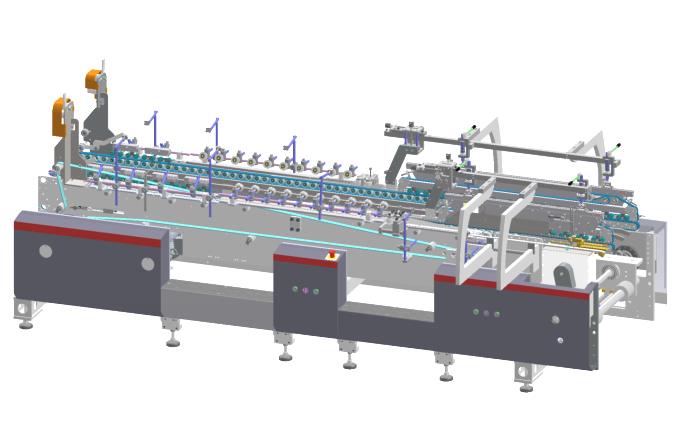

07/90° Transfer Unit

Full-servo-driven transfer rollers for precision operation Open-access platform with intuitive ergonomic controls High-capacity suction fans under rollers ensure vibration-free rotation |

08/Conveying Unit

Independent servo drives for upper/lower belt groups Decoupled belt movement mechanism rapidly adjusts front/rear positions to accommodate various box lengths |